Education

Defining TrueHVLP Electric Paint System Technology for Automotive, Marine, and Aviation Painting

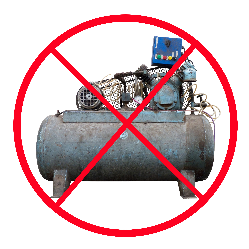

Maxi-Miser® Electric Paint system technology is an air atomizing alternative to compressed air spraying. It’s important to note that an HVLP electric paint system is not an air compressor. Instead, it’s an alternative atomizing air supply source that provides a range of benefits over traditional compressed air spraying.

The Maxi-Miser® Electric Paint system is an independent complete paint spray system that doesn’t require a compressor, making it easy to move around if necessary. It also dramatically reduces overspray, with transfer efficiency of 80-90% for all paints and primers, resulting in significant savings with less coating consumption (25-50% or better). The system offers superb control, which means less masking, and it’s easy to transition from conventional spray. Cleanup and maintenance are also straightforward, and the system produces a Class A fine finish.

The Maxi-Miser® Electric Paint system is an independent complete paint spray system that doesn’t require a compressor, making it easy to move around if necessary. It also dramatically reduces overspray, with transfer efficiency of 80-90% for all paints and primers, resulting in significant savings with less coating consumption (25-50% or better). The system offers superb control, which means less masking, and it’s easy to transition from conventional spray. Cleanup and maintenance are also straightforward, and the system produces a Class A fine finish.

The Maxi-Miser®

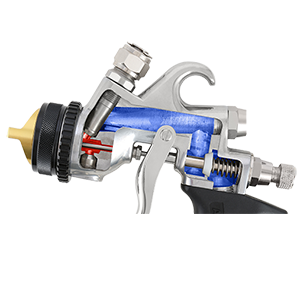

The Maxi-Miser® electric paint systems comprises three components: the electric paint unit (air source), air hose with quick-connect couplers, and HVLP specially designed Spray gun. Maxi-Miser® HVLP electric paint units house industrial bypass motors that produce 65+cfm at 10psi or less. The rotational friction of the

electric paint systems comprises three components: the electric paint unit (air source), air hose with quick-connect couplers, and HVLP specially designed Spray gun. Maxi-Miser® HVLP electric paint units house industrial bypass motors that produce 65+cfm at 10psi or less. The rotational friction of the  motor creates consistent clean dry air.

motor creates consistent clean dry air.  When turbine spray-generated air is directed through a custom-designed HVLP spray gun that incorporates larger air passageways including larger holes in the air cap, you achieve ultra-efficient low-pressure atomization, resulting in dramatically less overspray, substantial material savings, and a cleaner work environment.

When turbine spray-generated air is directed through a custom-designed HVLP spray gun that incorporates larger air passageways including larger holes in the air cap, you achieve ultra-efficient low-pressure atomization, resulting in dramatically less overspray, substantial material savings, and a cleaner work environment.

Apollo Sprayers MAXI-MISER TrueHVLP electric paint system Technology uses exclusive and unique HVLP technology that provide multiple pressure settings, as well as minimizing air relief to maximize the highest pressures each individual motor can produce while ensuring high performance and longevity. The 3000 PRO and PRECISION models offer visible and variable pressure control along with additional precision features not available elsewhere, with a US Patent (9,599,117 B2).

Understanding the realistically available or maximum air pressure is crucial in relating various coatings and finishes to the equipment. The beauty of the MAXI-MISER Electric Paint Systems is the ability to dial in the most efficient pressure (1/10th PSI accuracy) for a particular coating based on viscosity or difficulty to atomize a finish. This results in the highest product efficiency, lowest amount of overspray, highest cost savings, cleanest work environment, and the best protection of our environment.

Understanding the realistically available or maximum air pressure is crucial in relating various coatings and finishes to the equipment. The beauty of the MAXI-MISER Electric Paint Systems is the ability to dial in the most efficient pressure (1/10th PSI accuracy) for a particular coating based on viscosity or difficulty to atomize a finish. This results in the highest product efficiency, lowest amount of overspray, highest cost savings, cleanest work environment, and the best protection of our environment.

Apollo Spray has carefully documented performance, application speed, mil-build, paint savings, nozzle/needle and air cap selection, color accuracy, blending features, and finish results. High production capability is available using a pressure pot as a source for fluid delivery as an option to a standard cup installed on a spray gun where larger paint volume is necessary.

In conclusion, Apollo Sprayers International Inc. has been manufacturing Electric Paint Systems in the USA for over 50 years. They understand the importance of the appearance of your project, and their goal is to provide equipment and technology that meets the needs of today’s environmental concerns while providing easy access and performance to achieve the perfect finish. The Maxi-Miser® Electric Paint System technology, with its many benefits and features accomplishes this. Join our family today and appreciate the benefits of Maxi-Miser® HVLP Electric Painting Systems.